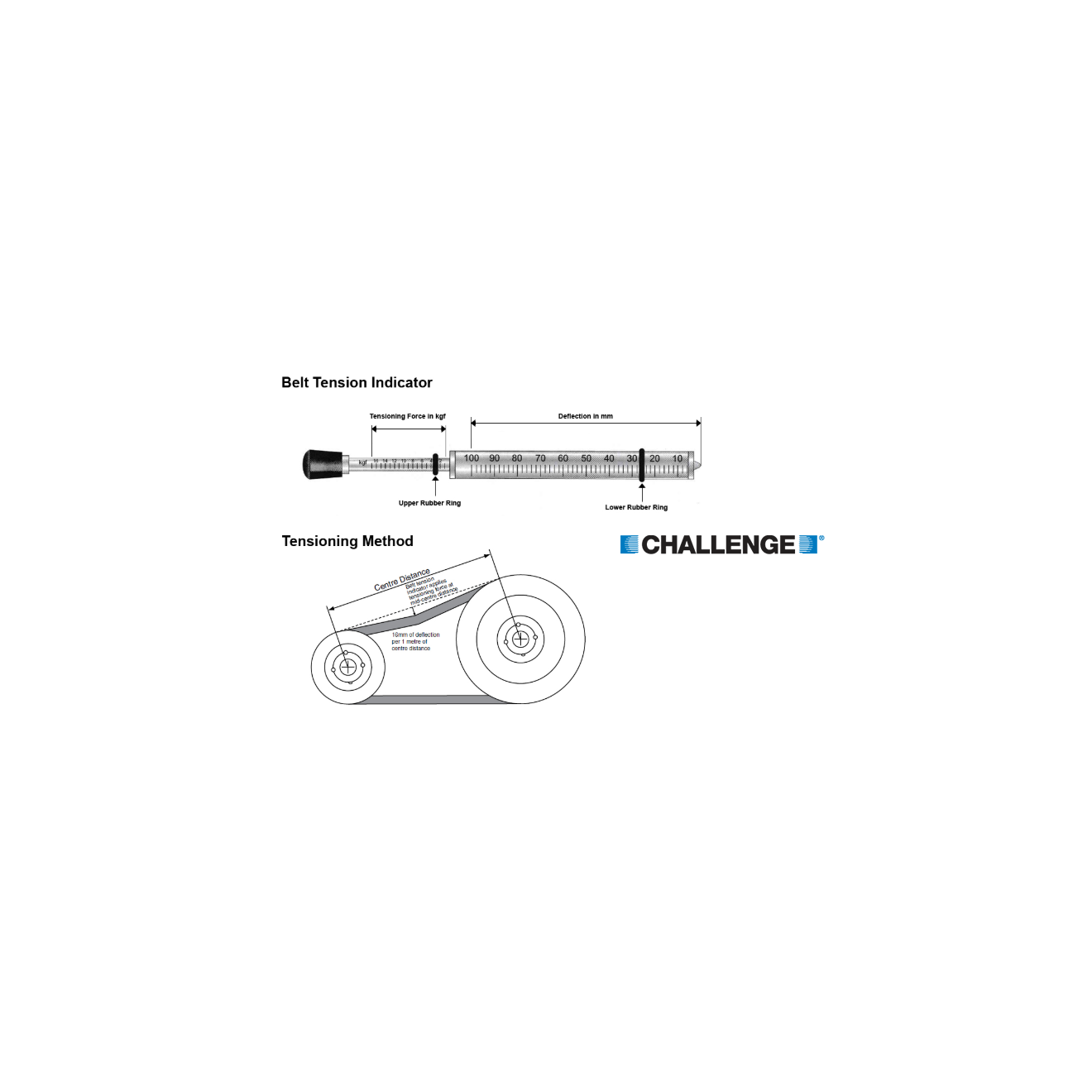

Challenge Belt Tension Gauge For V & Wedge Belt A, B, C, SPZ, SPA, SPB, SPC, Z

we only supply the highest quality products with the premier SKF brand your requirement for high quality bearings are here. We supply other quality brands like NTN, Medway, Koyo, NKE, ZEN, PFI, FAG, INA, IKO, PIX etc.

"We are official Dunlop BTL & Challenge Power Transmission distributors for Devon and Cornwall"

we only supply the highest quality products with the premier SKF brand your requirement for high quality bearings are here. We supply other quality brands like NTN, Medway, Koyo, NKE, ZEN, PFI, FAG, INA, IKO, PIX etc.

"We are official Dunlop BTL & Challenge Power Transmission distributors for Devon and Cornwall"

we only supply the highest quality products with the premier SKF brand your requirement for high quality bearings are here. We supply other quality brands like NTN, Medway, Koyo, NKE, ZEN, PFI, FAG, INA, IKO, PIX etc.

"We are official Dunlop BTL & Challenge Power Transmission distributors for Devon and Cornwall"

we only supply the highest quality products with the premier SKF brand your requirement for high quality bearings are here. We supply other quality brands like NTN, Medway, Koyo, NKE, ZEN, PFI, FAG, INA, IKO, PIX etc.

"We are official Dunlop BTL & Challenge Power Transmission distributors for Devon and Cornwall"

we only supply the highest quality products with the premier SKF brand your requirement for high quality bearings are here. We supply other quality brands like NTN, Medway, Koyo, NKE, ZEN, PFI, FAG, INA, IKO, PIX etc.

"We are official Dunlop BTL & Challenge Power Transmission distributors for Devon and Cornwall"

This Challenge belt tension gauge V and Wedge belts are manufactured to ensure precise length and to stay matched during storage and on the drive for many years. This also ensures that each belt, when correctly tensioned, will take the correct share of the load to be transmitted, thus helping to achieve maximum life for the drive. We recommend using the Challenge Belt Tensioning Gauge to obtain the correct tension for the drive thus ensuring optimum life from the belts. This method has been verified by successful drives globally.

How to use the Challenge Belt Tension Gauge:

1. Install the belts to be a snug fit around the pulleys

2. Rotate the pulleys a few revolutions to allow the belts to sit correctly in the pulley grooves. Be careful not to trap fingers!

3. Calculate the deflection in mm on a basis of 16 mm per metre of centre distance

4. Set the lower black rubber ring on the large tube to the deflection required in mm

5. Set the upper ring (on the metal rod) against the top of the large tube

6. Place the belt tension indicator on top of the belt at the middle of the centre distance and apply a force at right angles to the belt, deflecting it to the point where the lower rubber ring is level with the top of an adjacent belt.

7. Read off the tensioning force value indicated by the bottom edge of the upper rubber ring

8. Compare this force to the value in the table and adjust the tension until the correct value is attained

9. A new drive should be tensioned to the 1.3 x tensioning force to allow for belt tension decay during the initial bedding in period. After approximately 30 minutes of running and thereafter, the tension should be set to the basic tensioning value

10. For a single belt drive, use a straight edge across the two pulleys to act as a reference point and apply the Challenge Belt Tension Gauge as per point 6.

11. If a Challenge Belt Tension Gauge is not available, using a spring balance and rule is acceptable.

| Hazardous Item | No |

|---|